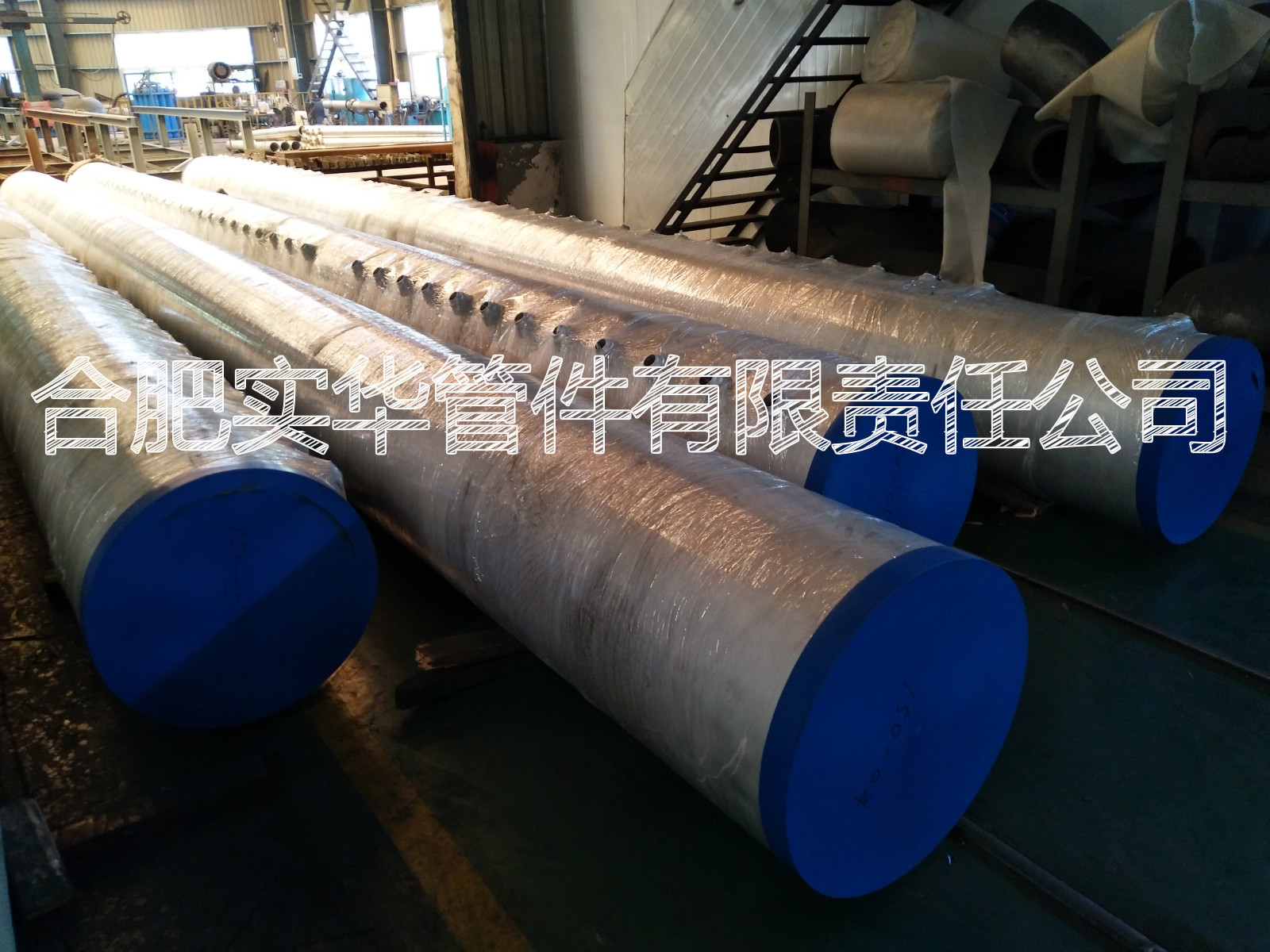

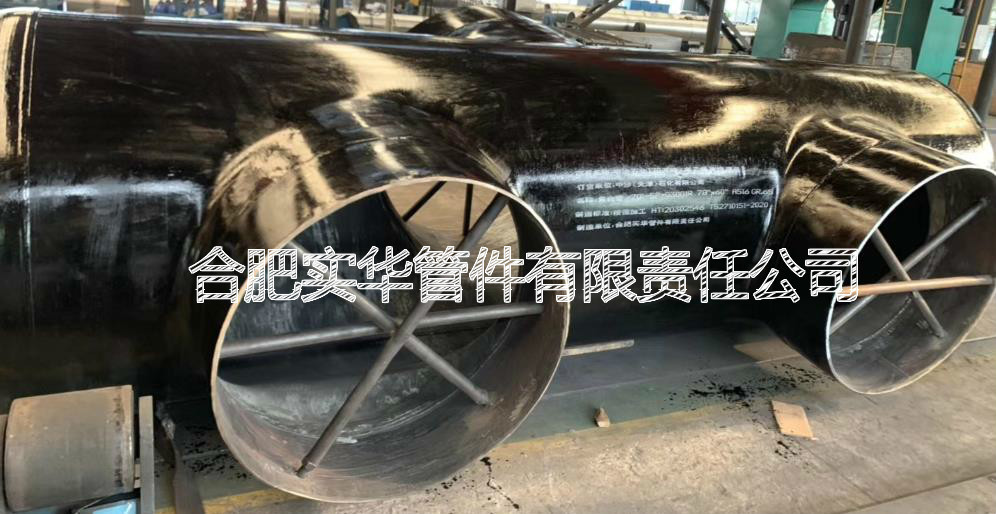

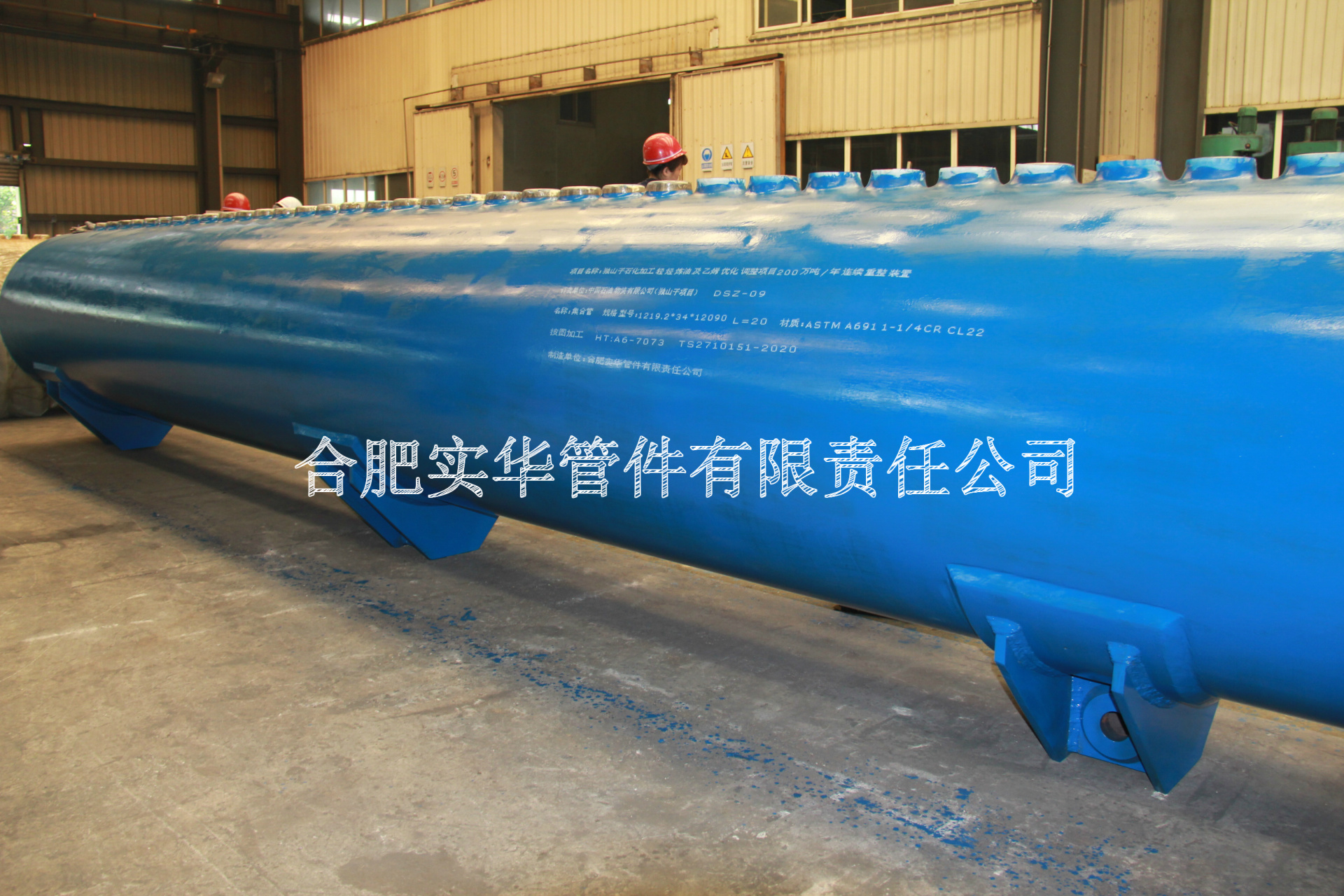

The reducer produced by our company adopts the hot pressing manufacturing process. Products are widely used in petroleum, chemical, electric power, metallurgy, machinery, textile, food, pharmaceutical, shipbuilding and other industries.

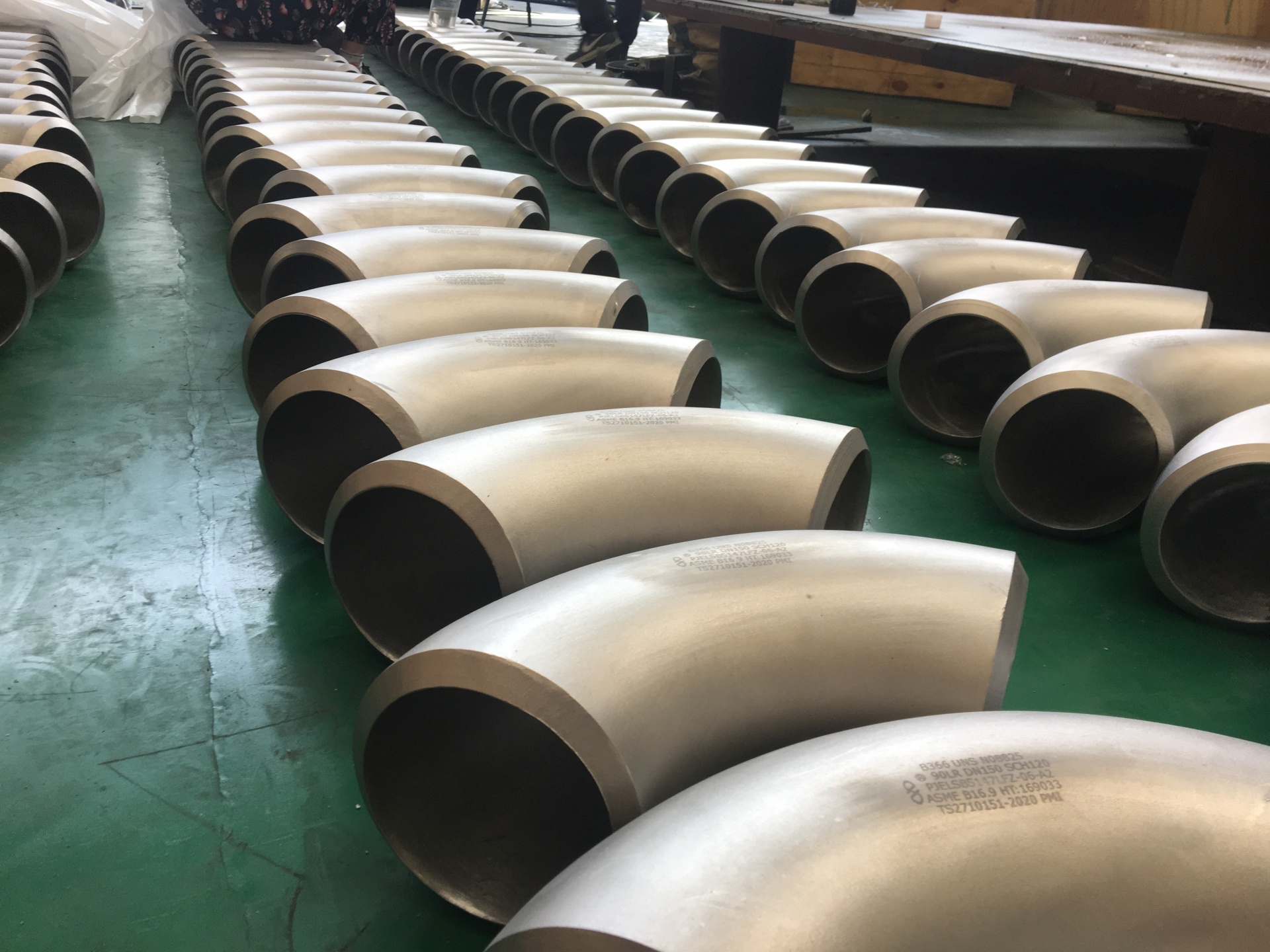

The main materials are: carbon steel, alloy steel, stainless steel, duplex steel, nickel-based alloys, etc.

Product specifications: DN25-DN600

Wall thickness grade: Sch10s, Sch20, Sch40, Sch80, Sch100, Sch120, Sch140, Sch160, STD, XS, XXS

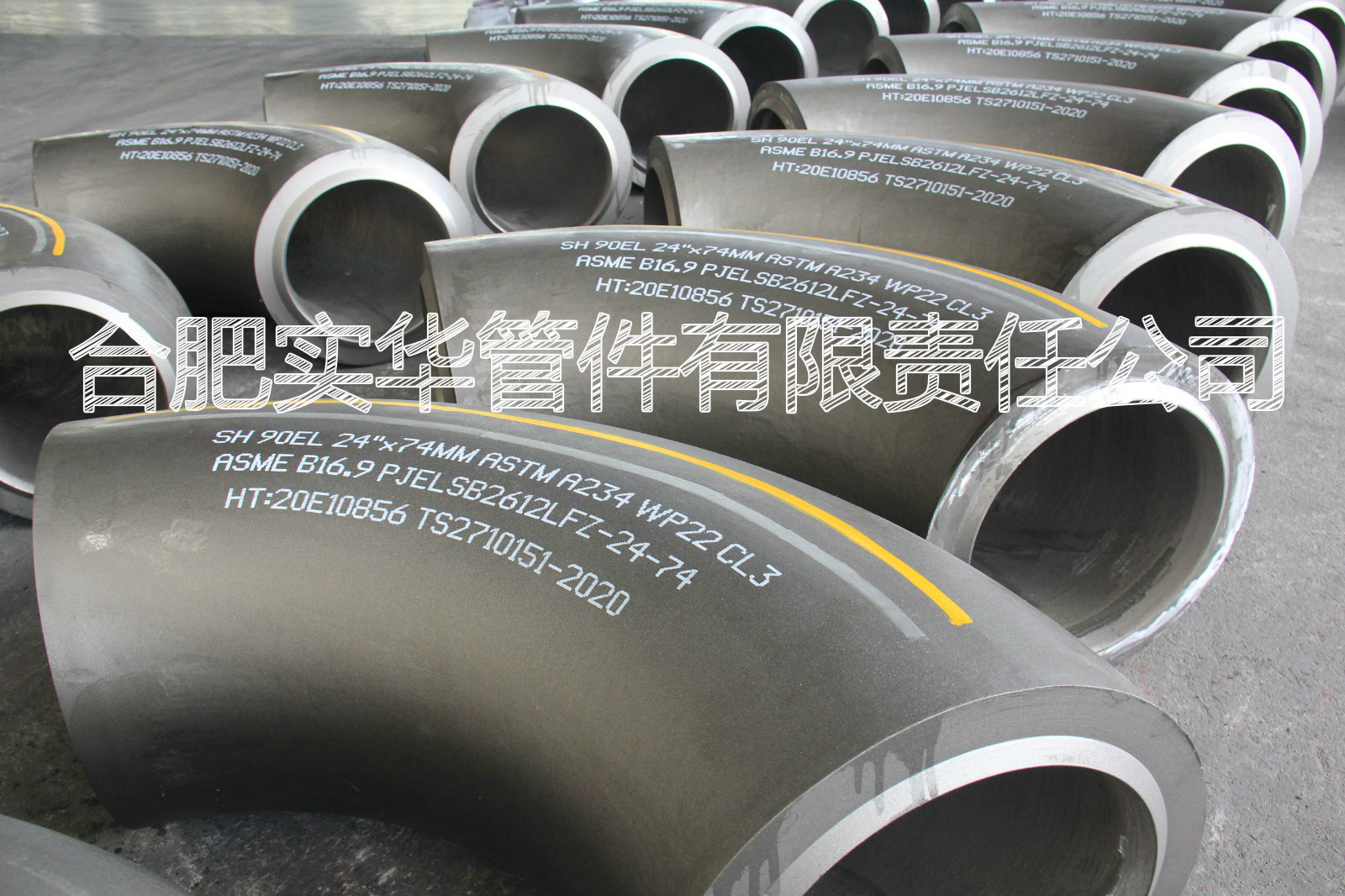

Manufacturing standard: GB/T12459, SH/T3408, ASME B16.9

NO8825 eccentric reducer

UNS NO8825 (Incoloy825) austenitic nickel-iron-chromium alloy.

Overview of Incoloy825 characteristics and application fields: (American approximate grade Incoloy Alloy825)

The alloy is a general engineering alloy, in the oxidation and reduction environment has acid and alkali metal corrosion resistance and high nickel composition makes the alloy has effective resistance to stress corrosion cracking. The corrosion resistance in various media is very good, such as sulfuric acid, phosphoric acid, nitric acid and organic acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solution. The comprehensive performance of the alloy is manifested in the nuclear combustion dissolver with various corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide are all processed in the same equipment. It is applied to various industrial fields with operating temperature not exceeding 550 ℃, such as heating pipes, containers, baskets and chains for sulfuric acid pickling plants, seawater cooling heat exchangers, marine product piping systems, acid gas environment pipelines, heat exchangers in phosphoric acid production, evaporators, washing, immersion pipes, air heat exchangers in petroleum refining, food engineering, chemical processes, flame retardant alloys for high-pressure oxygen applications, etc.

Message

Message Map

Map About

About Job

Job